In a kitchen design, the kitchen cabinets are not only functional, they are a major focal point that can also help to establish your style. Choosing the right cabinet construction might not be quite as exciting as picking out your chef’s appliances, but how they are made is one of the most important decisions you’ll make in the long-term functionality and usability of your kitchen.

What Exactly is a Cabinet Box?

When your designer is talking about the cabinet box, they are talking about the physical infrastructure of the cabinet, minus the hardware, trim and doors. The cabinet box consists of a floor, sides, a back, a top, shelving, and if it is a base cabinet, a toe-kick.

How the cabinet is constructed can very between manufacturers. However, there are only two styles of kitchen cabinet boxes. framed and unframed or frameless.

Frameless Cabinets

Also called European-style, these cabinets have no face frame, meaning the drawers and doors attach directly to the box. Frameless cabinets have a more contemporary look, and it’s easier to access the inside of the cabinet.

Frameless cabinet construction’s durability relies on the quality of the material used. If done with inexpensive materials, constructing a box without a face frame can compromise the structural integrity of the cabinet. If you want the benefits of a contemporary look and feel, but prefer a framed cabinet, consider using a full overlay door as a good compromise.

Framed Cabinets

Also known as face-frame, consists of a box and a face frame. Framed construction incorporates planks of wood which “frame” around the outer edge of the box to which the doors and drawers attach. This construction consists of a basic wooden box, to which several pieces of wood are fastened to the front, creating what looks like an attached flat picture frame.

The inside edge of the frame extends into the box and is used to attach the cabinet doors. The edges of the frame are flush with the outside edges of the box. The face frame reinforces the cabinet box providing sturdy construction that will last for many years. Framed cabinets come with three different door styles. A full-overlay door completely covers the frame. Partial overlay doors mean the frame is partially covered, and inset doors and drawers are designed to fit within the frame with the frame fully exposed.

View Our Kitchen Design Portfolio

Cabinet Construction: Materials

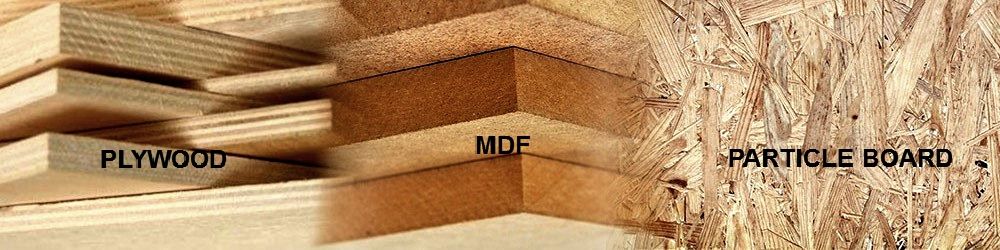

Kitchen cabinets are typically constructed of three types of “engineered” woods. All have their place in your kitchen design, depending on the type of wood used in the construction. They can vary widely in price. Better materials mean better quality and will last longer and stand up to daily use. It’s essential to buy the best cabinet boxes you can afford.

Plywood

This is the most expensive choice and is generally what your designer means when they say the cabinets are of “solid-wood” construction. It’s the strongest and most structurally sound material for cabinet construction. Plywood consists of thick layers of wood veneer that are glued together in contrasting grain patterns to add strength. The grade of the plywood depends on the number of layers, the thickness and grade of the wood used. All of these directly contribute to the quality of the box.

Plywood is easily painted or finished and accepts veneers and laminates well. In locations that experience high humidity, like Alabama, solid-wood cabinets may be prone to warping. Using marine-grade plywood in their construction is an excellent choice. Today, there are “green” plywood options that emit fewer VOCs.

MDF (medium-density fiberboard)

MDF is a structurally sound, solid material. It too takes veneers well, and you’ll see many products that use MDF along with solids and veneers in their construction. MDF is made by gluing wood fibers together. There is some concern about off-gassing formaldehyde, which is sometimes used in resin glues. Talk to your contractor. Today, some manufacturers use low VOC emitting materials.

Particle Board

If you’re working with a tight budget, particleboard may be a good choice. Rather than using wood fibers and veneers, it’s typically constructed from sawdust and wood scraps bound by resin. Particleboard contains higher levels of VOCs than either particleboard or plywood.

The construction of particleboard makes it challenging to use screws, and if you need to disassemble and reassemble your cabinet boxes, they may not survive.

Particleboard and MDF can expand when exposed to moisture or high humidity. Both hold veneers well, but MDF is a denser material. If VOCs are a concern, speak with your contractor or designer. There are materials available that minimize off-gassing.

While the material is an important consideration, ultimately, how your kitchen cabinets are constructed is critical. The construction methods used can vary widely, by the manufacturer and the level of quality you pay for. Make sure that whatever cabinets you choose whether custom or stock (more on this in a minute), the manufacturer uses proper joinery techniques. Strong joints equal durable cabinets. Mortise and tenon, or dovetailed joints connected using glue, nails, and screws make the strongest, most durable connection.

Stock, Semi-Custom or Custom Cabinets

When it comes to your kitchen cabinets, you have three cabinet types to choose from: stock, semi-custom, and custom/premium cabinetry. Each level of the build has elements to consider. Your contractor and designer will examine your wants, needs, and budget when determining which level of cabinetry is right for your kitchen.

Stock Cabinets

Stock cabinets are the lowest cost option. They are a good choice if you are working with a limited budget, or you’d rather splurge on upgraded countertops, fixtures, and other elements like appliances. Stock cabinets are usually limited in colors, styles, and sizes. You also need to understand that not all stock cabinets are built to last, so you need to look closely at how they are built to make sure you get a quality-built product. Many stock cabinets have size limitations, and that can result in an inefficient kitchen layout.

Bontina’s stock cabinetry line is produced by a high-quality manufacturer who offers options like filler strips and panels that provide our clients with a semi-custom look.

Semi-Custom Cabinets

Semi-custom cabinets allow your designer to create a kitchen design that will fit perfectly into your space and often have features that are not available in stock cabinets. Typically, stock cabinets are available in three-inch size increments (9”, 12”, 15” etc.). Semi-custom kitchen cabinets start with a standard size cabinet but are customizable to within 1/16”.

Custom Cabinetry

Custom Cabinetry can often be the most expensive option. However, if you have the budget, custom cabinets give you the ability to create a design that is unique to your home and will precisely meet your needs, both aesthetically and functionally. With custom cabinetry, you have more choices of features, can use exotic wood species, and are built to your exact specifications.

Your kitchen cabinetry is a critical element of your kitchen’s design and functionality. Here at Bontina Kitchen and Bath, we partner with top manufacturers of high-quality cabinetry products. With our clients to provide cabinetry that meets their lifestyle needs, aesthetic vision, and budget.